For One Piece TCG enthusiasts and collectors, preserving the integrity of booster boxes is more than a habit—it’s a commitment to safeguarding both sentimental value and potential investment. A high-quality One Piece booster box acrylic case isn’t just a protective layer; it’s a shield against dust, moisture, scratches, and the wear and tear of time that can diminish the condition of your prized One Piece booster boxes. Whether you’re a casual collector looking to keep your first booster box in mint condition or a reseller aiming to maintain product value for customers, sourcing the right acrylic case from a reliable manufacturer is critical.

But here’s the challenge: the market is flooded with low-quality acrylic cases that crack easily, discolor over time, or fail to fit One Piece booster boxes properly. Worse, untrustworthy manufacturers may cut corners on materials, use toxic chemicals in production, or deliver inconsistent products—leaving you with cases that do more harm than good. So how do you navigate this crowded landscape and find a manufacturer that delivers on quality, consistency, and reliability?

In this comprehensive guide, we’ll walk you through every step of sourcing high-quality One Piece booster box acrylic cases. From understanding the key features that define a top-tier case to vetting manufacturers, negotiating terms, and ensuring compliance, we’ll cover everything you need to know to make informed decisions. We’ll also share insider tips, common pitfalls to avoid, and answers to frequently asked questions to help you streamline the sourcing process.

Why High-Quality Acrylic Matters for One Piece Booster Box Preservation

Before diving into the sourcing process, it’s essential to understand why not all acrylic cases are created equal—and why investing in quality is non-negotiable for One Piece booster box collectors. One Piece TCG booster boxes are more than just containers for cards; they’re collectibles in their own right. Limited-edition boxes, first-print runs, or boxes from popular arcs (like the Wano Country or Marineford sets) often appreciate over time, but only if they remain in “mint” or “near-mint” condition.

Low-quality acrylic cases pose several risks to your booster boxes:

• Discoloration: Cheap acrylic (often made with recycled or impure materials) tends to yellow over time when exposed to sunlight or artificial light. This not only ruins the aesthetic of the case but can also transfer subtle discoloration to the booster box’s artwork.

• Cracking and Brittleness: Thin or poorly formulated acrylic is prone to cracking under minimal pressure—whether from accidental bumps, temperature fluctuations, or even the weight of stacking multiple cases. A cracked case exposes the booster box to dust and moisture.

• Poor Fit: Ill-fitting cases (either too tight or too loose) can damage the booster box. A tight case may bend the box’s edges, while a loose one allows the box to shift inside, causing friction and scratches.

• Toxic Chemicals: Some low-cost manufacturers use harmful additives or solvents in acrylic production. These chemicals can off-gas over time, leaving a sticky residue on the booster box or even damaging the paper and ink of the box’s design.

High-quality acrylic, on the other hand, addresses all these concerns. Medical-grade or cast acrylic (the gold standard for collectible protection) is crystal clear, resistant to yellowing, impact-resistant, and non-toxic. It’s also more durable, ensuring your booster boxes stay protected for years—if not decades.

Key Features to Look for in High-Quality One Piece Booster Box Acrylic Cases

To source the best acrylic cases, you need to know exactly what features to prioritize. Not all cases labeled “high-quality” deliver on their promises, so focus on these non-negotiable attributes when evaluating products:

1. Acrylic Material: Cast vs. Extruded

The first and most critical feature is the type of acrylic used. There are two main types: cast acrylic and extruded acrylic. For One Piece booster box cases, cast acrylic is superior for several reasons:

• Clarity: Cast acrylic has exceptional transparency, allowing you to showcase the booster box’s artwork without distortion or cloudiness.

• Yellowing Resistance: It contains fewer impurities than extruded acrylic, making it highly resistant to UV damage and yellowing. This is crucial if you display your cases near windows or under lights.

• Impact Resistance: Cast acrylic is more durable and less prone to cracking than extruded acrylic, which is softer and more likely to chip.

• Consistency: Cast acrylic is manufactured in batches with strict quality control, ensuring uniform thickness and density—something extruded acrylic often lacks.

Avoid manufacturers that use extruded acrylic for collectible cases, as it’s better suited for industrial applications (like signage) than delicate preservation.

2. Thickness and Durability

The thickness of the acrylic directly impacts its durability. For One Piece booster boxes (which typically measure around 8.5 x 6 x 2 inches), a case made with 1/8 inch (3mm) to 1/4 inch (6mm) thick acrylic is ideal. Thinner acrylic (1mm or 2mm) may be lightweight but will bend or crack easily, while thicker acrylic (over 6mm) can be unnecessarily heavy and expensive.

Ask manufacturers for the exact thickness of their cases and request samples to test durability—press gently on the edges to see if it bends, and check for any visible bubbles or imperfections in the material.

3. Precision Fit for One Piece Booster Boxes

One Piece booster boxes have standard dimensions, but there can be minor variations between sets (e.g., special edition boxes may be slightly thicker). A high-quality case should be custom-sized to fit standard One Piece booster boxes with a snug—but not tight—fit. The case should slide on easily without forcing, and the booster box should not shift inside.

Look for manufacturers that specialize in TCG or collectible cases, as they’re more likely to have precise measurements for One Piece boxes. If you’re sourcing for a specific set, provide the exact dimensions to the manufacturer to ensure a perfect fit.

4. Protective Features

The best acrylic cases go beyond basic protection with additional features that enhance preservation:

• UV Protection: Some premium acrylic cases are treated with a UV-resistant coating to block harmful UV rays, further preventing yellowing and protecting the booster box’s artwork from fading.

• Anti-Scratch Coating: A scratch-resistant coating keeps the case looking crystal clear, even with regular handling. This is especially important if you plan to display or transport the cases.

• Dust-Proof Seals: A tight, dust-proof seal around the edges of the case prevents dust from accumulating inside. Look for cases with a lip or groove that creates a secure closure.

• Stackable Design: If you have multiple booster boxes, a stackable case design saves space and prevents the bottom cases from being crushed. Ensure the top of the case has a flat surface and the bottom has a recess that locks into place with the case below.

5. Aesthetic and Functional Details

While protection is the top priority, aesthetic and functional details can elevate the value of the case:

• Edge Polishing: Smooth, polished edges prevent scratches on your hands or other cases and give the product a premium look.

• Openings for Labeling: Some cases have a small cutout or clear panel where you can insert a label with the booster box’s set name, year, or condition—useful for organization.

• Lightweight yet Sturdy: The case should be easy to carry or move without sacrificing durability.

How to Identify Reliable Manufacturers of Acrylic Cases

Once you know what features to look for in a case, the next step is finding a manufacturer that can deliver on these standards. Reliable manufacturers aren’t just suppliers—they’re partners who understand your needs and prioritize quality. Here’s how to identify them:

1. Start with Niche Specialization

The best manufacturers for One Piece booster box acrylic cases are those that specialize in TCG, collectible, or hobby-related acrylic products. General acrylic manufacturers may produce high-quality material, but they won’t have the precise measurements or understanding of collectible preservation needs that niche manufacturers do.

To find niche manufacturers:

• Search with Targeted Keywords: Use terms like “One Piece TCG acrylic case manufacturer,” “collectible booster box acrylic supplier,” or “premium TCG display case maker” on Google, Alibaba, or Thomasnet. Avoid generic terms like “acrylic box manufacturer,” which will yield thousands of irrelevant results.

• Check Collector Communities: Forums like Reddit’s r/OnePieceTCG, TCGPlayer’s forums, or Facebook groups for One Piece collectors are goldmines for recommendations. Ask other collectors which cases they use and who supplied them—word-of-mouth referrals are often the most reliable.

• Attend Hobby Trade Shows: Events like the North American International Toy Fair, Gen Con, or local TCG conventions often have booths for acrylic case manufacturers. This gives you the chance to see samples in person, ask questions, and build relationships with suppliers.

2. Vet Manufacturers for Quality and Reliability

Once you have a list of potential manufacturers, it’s time to vet them thoroughly. Don’t skip this step—cutting corners here can lead to costly mistakes (like receiving 1000 faulty cases).

Request Samples First

The single most important thing you can do is request a sample case before placing a large order. A sample allows you to test:

• The quality of the acrylic (clarity, thickness, yellowing resistance).

• The fit (does it match your One Piece booster box?).

• The craftsmanship (polished edges, secure seals, no bubbles or defects).

• The durability (does it bend or crack under light pressure?).

Most reputable manufacturers will charge a small fee for samples (often refundable if you place a large order) and cover shipping or split the cost. If a manufacturer refuses to send a sample, walk away—this is a major red flag.

Check Certifications and Compliance

Reliable manufacturers adhere to industry standards and hold relevant certifications. Look for:

• Material Certifications: Ask if the acrylic is FDA-approved (for non-toxicity) or meets ISO standards. Cast acrylic should have a certification from the manufacturer (like Lucite or Plexiglas, which are top brands).

• Quality Management Certifications: Certifications like ISO 9001 indicate that the manufacturer has a structured quality control process in place.

• Compliance with Safety Standards: If you’re sourcing from overseas (e.g., China, Taiwan, or South Korea), ensure the manufacturer complies with EU REACH or US CPSIA standards to avoid importing products with toxic chemicals.

Read Reviews and Check References

Look for reviews of the manufacturer online. Check platforms like Alibaba (for overseas suppliers), Google Reviews, or Trustpilot. Pay attention to reviews from other TCG collectors or resellers—their feedback will be more relevant than general customers.

Also, ask the manufacturer for references. A reputable supplier will be happy to share contact information for past clients. Reach out to these references and ask:

• Was the product quality consistent with the sample?

• Did the manufacturer deliver on time?

• How responsive was their customer service if issues arose?

• Would you work with them again?

Evaluate Communication and Customer Service

Reliable manufacturers prioritize clear communication. Pay attention to how they respond to your initial inquiries: do they answer questions promptly (within 24-48 hours)? Do they provide detailed, transparent information about their products, pricing, and lead times? Or do they give vague answers or avoid questions about material quality?

Poor communication early on is a sign of bigger issues down the line. For example, if a manufacturer takes a week to respond to your sample request, they’re likely to be slow with order fulfillment or problem-solving.

3. Consider Location: Domestic vs. Overseas Manufacturers

When sourcing acrylic cases, you’ll need to decide between domestic (local to your country) and overseas manufacturers. Both have pros and cons, so weigh them based on your needs:

Domestic Manufacturers (e.g., US, EU, Japan)

Pros:

• Faster shipping and shorter lead times (typically 1-2 weeks vs. 4-6 weeks for overseas).

• Easier communication (same time zone, no language barriers).

• Strict quality and safety standards (less risk of toxic materials).

• Lower shipping costs and no customs fees.

• Better for small orders (many overseas manufacturers have high minimum order quantities, or MOQs).

Cons:

• Higher per-unit costs (domestic labor and materials are more expensive).

• Fewer options (the number of niche acrylic case manufacturers may be limited).

Overseas Manufacturers (e.g., China, Taiwan, South Korea)

Pros:

• Lower per-unit costs (ideal for large orders or resellers).

• A wide range of manufacturers specializing in acrylic products (more options to choose from).

• Ability to customize cases (many overseas manufacturers offer custom sizes, colors, or branding).

Cons:

• Longer lead times (4-6 weeks for production, plus 2-4 weeks for shipping).

• Language barriers (may lead to miscommunication about specifications).

• Higher MOQs (many require orders of 100+ units).

• Customs fees, import taxes, and shipping costs can add up.

• Increased risk of quality issues (requires more rigorous vetting).

For most casual collectors or small-scale resellers, domestic manufacturers are the best choice. For large-scale resellers or businesses looking to brand their cases, overseas manufacturers may offer better value—provided you vet them thoroughly and order samples first.

Negotiating with Manufacturers: Get the Best Deal Without Sacrificing Quality

Once you’ve identified a few reliable manufacturers, it’s time to negotiate terms. Negotiation isn’t just about getting the lowest price—it’s about securing a fair deal that includes quality guarantees, flexible payment terms, and clear delivery timelines. Here’s how to approach it:

1. Know Your Budget and Order Volume

Before negotiating, have a clear idea of your budget per unit and the volume you can commit to. Manufacturers are more likely to offer discounts for larger orders, so if you can commit to 100+ units instead of 20, you’ll have more leverage. Be transparent about your volume—lying about how much you can order will only damage trust later.

2. Prioritize Quality Over Price

It’s tempting to go for the lowest price, but sacrificing quality for a few cents per unit will cost you more in the long run (e.g., returns, negative reviews, or damaged booster boxes). Instead of asking, “Can you lower the price?”, ask, “Is there a way to get a discount for a larger order while maintaining the same quality as the sample?”

3. Negotiate Key Terms Beyond Price

Price is important, but these terms are equally critical:

• Minimum Order Quantity (MOQ): If the manufacturer’s MOQ is too high (e.g., 500 units), ask if they can lower it for a first-time order. Many will agree to a lower MOQ to build a long-term relationship.

• Quality Guarantees: Ask for a guarantee that if more than X% of the order is defective (e.g., cracked cases, poor fit), the manufacturer will replace the defective units for free or issue a refund.

• Delivery Timelines: Get a clear timeline for production and shipping, and ask for a discount if the order is delayed beyond the agreed-upon date.

• Payment Terms: Avoid paying 100% upfront. Most reputable manufacturers will accept a 30-50% deposit upfront and the remaining balance upon completion (or before shipping). For overseas orders, use a secure payment method like PayPal or a letter of credit to protect yourself.

• Customization: If you want custom features (e.g., UV coating, branded logos), ask if these can be added at a reasonable cost. Some manufacturers offer free customization for large orders.

4. Get Everything in Writing

Once you’ve agreed on terms, get a formal contract or purchase order that outlines:

• Product specifications (material, thickness, dimensions, features).

• Order quantity and per-unit price.

• Deposit and payment terms.

• Production and delivery timelines.

• Quality guarantee and defective product policy.

• Shipping and customs responsibilities (who pays for what).

A written agreement protects both you and the manufacturer and prevents miscommunication down the line.

5. Avoiding Common Pitfalls in Sourcing Acrylic Cases

Even with careful vetting, it’s easy to fall into common traps when sourcing acrylic cases. Here are the most frequent pitfalls and how to avoid them:

Falling for “Cheap” Acrylic

If a manufacturer’s price is significantly lower than others, it’s almost always because they’re using low-quality material (e.g., extruded acrylic, recycled acrylic, or acrylic mixed with plastic). A 1/8-inch cast acrylic case should cost between $3-$8 per unit (depending on order volume and features). If a manufacturer offers it for $1 per unit, it’s too good to be true.

Ignoring Minimum Order Quantities (MOQs) Without Negotiation

Many overseas manufacturers set high MOQs (e.g., 500-1000 units) to optimize production costs, but this can be a barrier for small collectors or new resellers. Failing to negotiate MOQs upfront may leave you stuck with more cases than you need, tying up capital in unsold inventory. To avoid this:

Be upfront about your current order capacity (e.g., “I can commit to 100 units now, but plan to scale to 500 within 6 months”).

Ask if the manufacturer offers a “trial MOQ” for first-time clients—many are willing to flex to build long-term relationships.

Consider partnering with other collectors or resellers to split a larger order, reducing individual risk while meeting the MOQ.

Overlooking Shipping and Customs Logistics

For overseas orders, shipping and customs can be a minefield if not planned for. Common issues include:

Unexpected fees: Customs duties, import taxes, and brokerage fees can add 20-40% to the total cost. Research your country’s import regulations (e.g., US CBP rules, EU customs codes for acrylic products) and ask the manufacturer to provide a commercial invoice with accurate product descriptions and values to avoid overcharging.

Damage during transit: Acrylic cases are fragile—ensure the manufacturer uses protective packaging (e.g., bubble wrap, rigid cartons, corner protectors) and offers shipping insurance. If cases arrive cracked or scratched, insurance will cover replacements.

Delays: Port congestion, customs inspections, or shipping carrier issues can extend delivery times beyond the estimated window. Build a buffer into your timeline (e.g., order 8 weeks in advance if you need cases for a convention) and confirm the manufacturer’s tracking and communication process for delayed shipments.

Skipping a Written Contract

Verbal agreements or vague email exchanges are risky—if the manufacturer fails to deliver on quality, quantity, or timelines, you’ll have no legal recourse. Even for small orders, always insist on a formal contract or detailed purchase order (PO) that includes:

Exact product specs (e.g., “1/8-inch cast acrylic, UV-resistant coating, dust-proof seal, fits standard One Piece booster boxes 8.5x6x2 inches”).

Defective product protocol (e.g., “Manufacturer will replace any defective units within 30 days of delivery, no cost to buyer”).

Shipping responsibilities (e.g., “Manufacturer covers production and FOB shipping; buyer covers customs and final delivery”).

Dispute resolution (e.g., “Any issues will be resolved via mediation before legal action”).

Neglecting Post-Purchase Support

A reliable manufacturer doesn’t disappear after delivering your order. Poor post-purchase support can be costly if you encounter issues like:

A batch of cases with inconsistent fit (e.g., 10% of cases are too tight).

Need for reorders with modified specs (e.g., a new One Piece set with larger boxes).

Questions about care (e.g., how to clean the acrylic without scratching it).

Before placing an order, ask the manufacturer:

How long their post-purchase support lasts (e.g., 6 months to 1 year).

How to contact support (email, phone, or a dedicated portal).

If they offer replacements or adjustments for future orders based on feedback.

Final Steps to Secure Your Sourcing Process

Once you’ve negotiated terms, signed a contract, and placed your order, follow these steps to ensure a smooth experience:

Stay in Communication: Check in with the manufacturer halfway through production to confirm progress and address any issues early. Ask for photos of the production line or finished samples to verify quality.

Inspect the Shipment Immediately: When cases arrive, unpack and inspect a random sample (10-15% of the order) within 48 hours. Check for cracks, poor fit, discoloration, or defects. If issues are found, document them with photos and contact the manufacturer immediately to invoke the quality guarantee.

Provide Feedback: After receiving and using the cases, share feedback with the manufacturer—positive or negative. This helps build trust and ensures they maintain (or improve) quality for future orders. For example, if the UV coating works well, let them know; if the stackable design could be more secure, suggest adjustments.

Build a Long-Term Relationship: If you’re happy with the product and service, consider partnering with the manufacturer for future orders. Long-term clients often receive better discounts, priority production, and customized solutions (e.g., exclusive colors or branding).

FAQ: Common Questions About Sourcing One Piece Booster Box Acrylic Cases

What’s the difference between cast and extruded acrylic for One Piece booster box cases?

Cast acrylic is the gold standard for collectible protection—offering superior clarity, UV resistance (no yellowing), impact durability, and consistent thickness. It’s formulated for preservation, making it ideal for safeguarding valuable One Piece boxes. Extruded acrylic is cheaper but softer, prone to chipping, cloudiness, and yellowing over time. It’s better for industrial use (e.g., signage) than delicate collectibles, as it fails to protect against scratches, moisture, or pressure-related damage. Always prioritize cast acrylic for long-term mint condition.

How do I ensure the acrylic case fits my One Piece booster box perfectly?

Start by confirming your box’s dimensions (standard One Piece TCG boxes are ~8.5x6x2 inches, but special editions may vary). Choose manufacturers specializing in TCG/collectible cases—they have precise measurements for popular sets (e.g., Wano Country, Marineford). Request a sample to test fit: the case should slide on easily, hold the box snugly (no shifting), and avoid bending edges. If sourcing for a specific set, share exact dimensions with the manufacturer for custom sizing. Avoid generic acrylic boxes, as ill-fitting cases cause friction or damage.

Are overseas manufacturers reliable for sourcing acrylic cases, and how do I mitigate risks?

Overseas manufacturers (e.g., China, Taiwan) offer lower per-unit costs and customization, but require rigorous vetting. Mitigate risks by: requesting samples to verify quality/fit; checking certifications (ISO 9001, REACH/CPSIA compliance); negotiating flexible MOQs for first orders; using secure payment methods (PayPal, letter of credit); and clarifying shipping insurance/packaging. Factor in longer lead times (8-10 weeks total) and customs fees. For small orders, domestic manufacturers are safer, but overseas works for large-scale resellers willing to invest in vetting.

What protective features should I look for in a high-quality acrylic case?

Essential protective features include UV-resistant coating (blocks fading/artwork damage), anti-scratch treatment (maintains clarity with handling), dust-proof seals (prevents debris buildup), and stackable design (saves space without crushing boxes). Polished edges prevent scratches to hands or other cases. For serious collectors, opt for FDA-approved non-toxic acrylic to avoid chemical off-gassing that damages box paper/ink. These features ensure your One Piece booster boxes stay protected from light, dust, moisture, and wear for years.

What’s a reasonable price for a high-quality One Piece booster box acrylic case, and how can I negotiate?

Expect to pay $3-$8 per unit for a 1/8-inch (3mm) cast acrylic case (varies by order volume and features). Prices below $2 likely indicate low-quality extruded/recycled acrylic—avoid these, as they risk damage. Negotiate by: committing to larger orders (100+ units) for discounts; asking for trial MOQs (lower for first-time buyers); bundling custom features (e.g., UV coating) for free with bulk orders; and securing price locks for repeat orders. Never sacrifice quality for cost—cheap cases lead to damaged collectibles and lost value. Always get price terms in writing with quality guarantees.

Summary

Sourcing high-quality One Piece booster box acrylic cases from reliable manufacturers requires a mix of research, vetting, and strategic negotiation—but the effort pays off in protecting your valuable collectibles. To recap the key steps:

Prioritize Quality Acrylic: Opt for cast acrylic (1/8-1/4 inch thick) with UV resistance, scratch protection, and a precise fit for One Piece booster boxes. Avoid extruded or recycled acrylic that risks discoloration, cracking, or damage to your boxes.

Find Niche Manufacturers: Focus on suppliers specializing in TCG/collectible cases—they understand preservation needs and precise measurements. Use targeted searches, collector communities, and trade shows to identify candidates.

Vet Thoroughly: Request samples to test quality and fit, check certifications (ISO, FDA, REACH/CPSIA), read reviews, and evaluate communication. Skip manufacturers that refuse samples or provide vague information.

Negotiate Smartly: Balance budget with quality, negotiate MOQs, secure quality guarantees and flexible payment terms, and get all agreements in writing.

Avoid Pitfalls: Steer clear of suspiciously cheap prices, plan for shipping/customs costs, and don’t skip post-purchase support.

By following this guide, you’ll not only find a manufacturer that delivers consistent, high-quality cases but also build a sourcing process that safeguards your investment—whether you’re a casual collector preserving a sentimental box or a reseller maintaining product value for customers. With the right case, your One Piece booster boxes will remain in mint condition for years to come, retaining both their sentimental and financial worth.

About Jayi Acrylic: Your Trusted One Piece Booster Box Acrylic Case Partner

At Jayi Acrylic, we take immense pride in crafting top-tier custom one piece booster box acrylic cases tailored for your cherished One Piece TCG collectibles. As China’s leading wholesale TCG acrylic case factory, we specialize in delivering high-quality, durable display and storage solutions designed exclusively for One Piece booster boxes—from limited-edition first-print runs to popular arc-themed sets.

Our cases are forged from premium cast acrylic, boasting crystal-clear visibility that showcases every detail of your booster box’s artwork and long-lasting durability to shield against scratches, dust, moisture, and impact. Whether you’re a seasoned collector preserving mint-condition boxes or a reseller safeguarding product value for customers, our custom designs blend elegance with uncompromising protection.

We cater to bulk orders and offer personalized designs (including precise sizing, UV-resistant coating, and stackable features) to meet your unique needs. Contact Jayi Acrylic today to elevate your One Piece booster box collection’s display and protection!

Have Questions? Get A Quote

Want to Know More About One Piece Acrylic Case?

Click the Button Now.

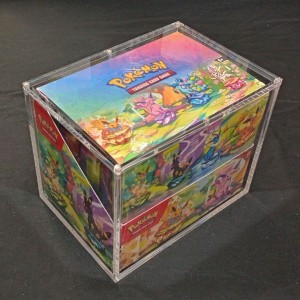

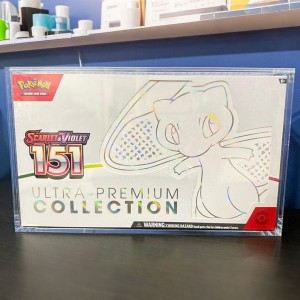

Our Custom Pokemon Acrylic Case Examples:

Acrylic Booster Pack Case

Japanese Booster Box Acrylic Case

Booster Pack Acrylic Dispenser

PSA Slab Acrylic Case

Charizard UPC Acrylic Case

Pokemon Slab Acrylic Frame

151 UPC Acrylic Case

MTG Booster Box Acrylic Case

Funko Pop Acrylic Case

Post time: Dec-16-2025