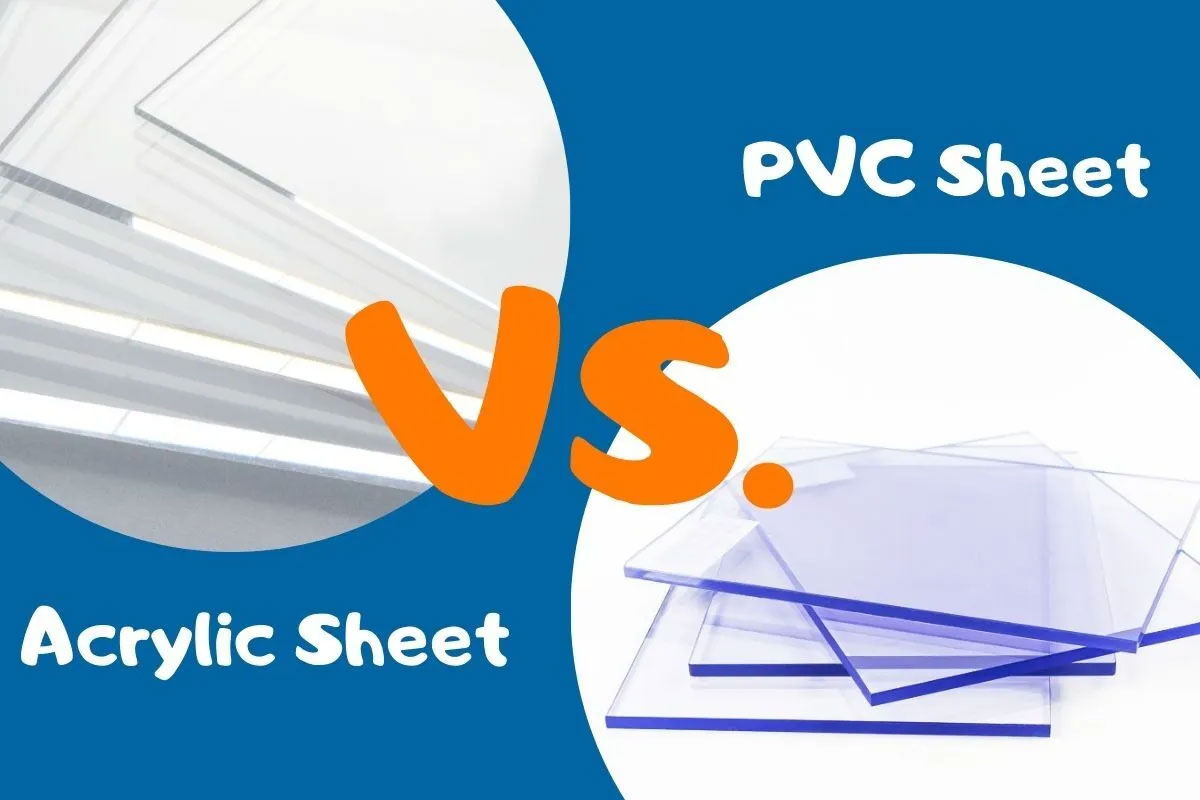

When it comes to choosing materials for home improvement, crafting, industrial projects, or commercial displays, two popular options often stand out: acrylic and PVC. At first glance, these two plastics might seem similar—they’re both durable, versatile, and used in a wide range of applications. However, dig a little deeper, and you’ll discover significant differences in their composition, properties, performance, and ideal uses. Choosing the wrong one can lead to project failures, increased costs, or short-lived results. In this comprehensive guide, we’ll break down the key distinctions between acrylic and PVC, helping you make an informed decision for your next project.

What Is Acrylic?

Acrylic, also known by its chemical name polymethyl methacrylate (PMMA) or the brand name Plexiglas, is a transparent thermoplastic polymer. First developed in the early 20th century, acrylic quickly gained popularity as an alternative to glass due to its lighter weight and greater impact resistance. Unlike some plastics, acrylic is derived from methyl methacrylate monomers, which undergo a polymerization process to form a hard, rigid material.

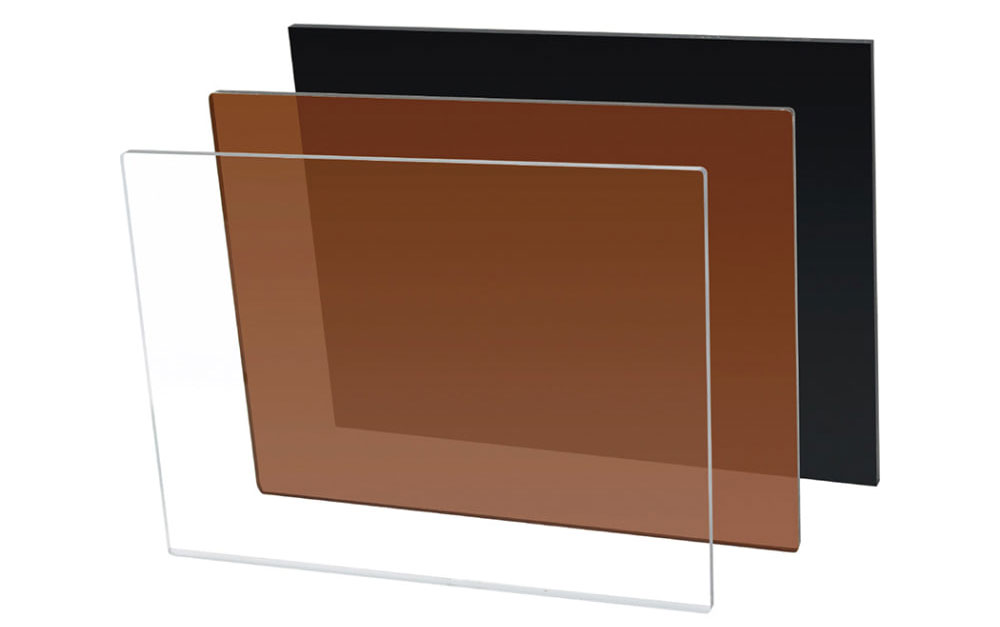

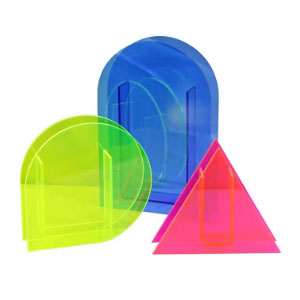

One of the most notable characteristics of acrylic is its exceptional clarity. It offers up to 92% light transmission, which is even higher than glass (which typically transmits 80-90% of light). This makes it a top choice for applications where transparency is critical. Additionally, acrylic is available in a variety of forms, including sheets, rods, tubes, and even cast or extruded options—each with slight variations in strength and flexibility.

What Is PVC?

PVC, short for polyvinyl chloride, is one of the most widely produced plastics in the world. It’s a synthetic polymer made from vinyl chloride monomers, and its composition can be modified with plasticizers to create either rigid or flexible forms. Rigid PVC (often called uPVC or unplasticized PVC) is stiff and strong, while flexible PVC (plasticized PVC) is malleable and used in applications like hoses, cables, and flooring.

PVC’s popularity stems from its affordability, durability, and resistance to moisture and chemicals. Unlike acrylic, PVC is naturally opaque, though it can be manufactured in transparent or colored versions with the addition of additives. It’s also highly moldable, making it suitable for complex shapes and profiles—another reason it’s a staple in construction and manufacturing.

Key Differences Between Acrylic and PVC

To truly understand how acrylic and PVC differ, we need to examine their core properties, performance in various conditions, and practical applications. Below is a detailed breakdown of the most important distinctions:

1. Transparency and Aesthetics

When it comes to clarity, acrylic is in a league of its own. As mentioned earlier, it boasts 92% light transmission, which is nearly identical to optical glass. This means acrylic sheets or products are crystal clear, with minimal distortion—perfect for applications where visibility is key, such as display cases, picture frames, skylights, and retail signage.

PVC, on the other hand, is naturally opaque. While transparent PVC exists, it never achieves the same level of clarity as acrylic. Transparent PVC often has a slight haze or yellowish tint, especially over time, and its light transmission maxes out at around 80%. Additionally, PVC is more commonly used in colored or white forms, where transparency isn’t a requirement. For example, white PVC is popular for window frames, pipes, and fencing, where a clean, uniform look is preferred over clarity.

Another aesthetic difference is color stability. Acrylic is highly resistant to yellowing when exposed to UV light, especially if it’s treated with a UV inhibitor. This makes it ideal for outdoor applications like patio enclosures or outdoor signage. PVC, however, is more prone to yellowing and discoloration over time, particularly when exposed to sunlight or harsh weather conditions. Rigid PVC may also become brittle and crack if left unprotected outdoors for extended periods.

2. Strength and Durability

Both acrylic and PVC are durable plastics, but their strength characteristics differ significantly—making them better suited for different tasks.

Acrylic is known for its high impact resistance. It’s up to 10 times more impact-resistant than glass, which is why it’s often used in safety applications like bulletproof windows (when layered), children’s play areas, and motorcycle windshields. However, acrylic is relatively rigid and can crack or shatter under extreme pressure or if dropped from a great height. It’s also prone to scratching—while minor scratches can be polished out, deep scratches may require replacement.

PVC, particularly rigid PVC, is strong and rigid but has lower impact resistance than acrylic. It’s less likely to shatter than glass but more likely to crack under sudden impacts compared to acrylic. However, PVC excels in compressive strength, which makes it ideal for applications like pipes, gutters, and structural components where it needs to withstand constant pressure. Flexible PVC, as the name suggests, is more malleable and resistant to bending, making it suitable for hoses, electrical insulation, and flooring.

When it comes to long-term durability, both materials perform well in indoor environments. But outdoors, acrylic has the edge due to its UV resistance. PVC can degrade over time in direct sunlight, leading to brittleness and discoloration. To combat this, PVC products used outdoors are often coated with UV stabilizers, but even then, they may not last as long as acrylic in harsh weather conditions.

3. Chemical Resistance

Chemical resistance is a critical factor for applications involving exposure to solvents, cleaners, or industrial chemicals. Here, PVC has a clear advantage over acrylic.

PVC is highly resistant to a wide range of chemicals, including acids, alkalis, oils, and solvents. This makes it a top choice for chemical storage tanks, laboratory equipment, pipes for chemical processing, and even pool liners (which are exposed to chlorine). It’s also resistant to water and moisture, which is why it’s commonly used in plumbing and outdoor irrigation systems.

Acrylic, by contrast, is more sensitive to chemicals. It can be damaged by solvents like acetone, alcohol, gasoline, and even some household cleaners (such as ammonia-based products). Exposure to these chemicals can cause acrylic to cloud, crack, or dissolve. While acrylic is resistant to water and mild detergents, it’s not suitable for applications involving harsh chemicals. For example, you wouldn’t use acrylic for a chemical storage container or a lab bench that comes into contact with solvents.

4. Heat Resistance

Heat resistance is another key difference between acrylic and PVC, as it affects their suitability for high-temperature applications.

Acrylic has a higher heat resistance than PVC. Its glass transition temperature (the temperature at which it softens) is around 105°C (221°F). This means acrylic can withstand moderate heat without warping or melting—making it suitable for applications like light fixtures, oven doors (as a safety glass), and decorative elements in kitchens. However, acrylic should not be exposed to temperatures above 160°C (320°F), as it will melt and release toxic fumes.

PVC has a lower glass transition temperature, around 80-85°C (176-185°F) for rigid PVC. At temperatures above 100°C (212°F), PVC can start to soften and warp, and at higher temperatures (around 160°C/320°F), it begins to decompose and release harmful chemicals like hydrogen chloride. This makes PVC unsuitable for high-temperature applications like oven parts or light fixtures that generate significant heat. However, PVC’s low heat resistance is not a problem for most indoor and outdoor applications where temperatures remain moderate, such as window frames, pipes, and flooring.

5. Weight

Weight is an important consideration for applications where portability or reduced structural load is key. Both acrylic and PVC are lighter than glass, but they differ from each other in density.

Acrylic has a density of approximately 1.19 g/cm³. This makes it about 50% lighter than glass (which has a density of 2.5 g/cm³) and slightly lighter than PVC. For example, a 1/4-inch thick acrylic sheet weighs less than a similar PVC sheet, making it easier to handle and install in applications like signage, display cases, or skylights where weight is a concern.

PVC has a higher density, around 1.38 g/cm³. While it’s still lighter than glass, it’s heavier than acrylic. This extra weight can be an advantage in applications where stability is important—for example, PVC pipes are less likely to shift or move in underground installations. But for applications where weight needs to be minimized (like aircraft windows or portable displays), acrylic is the better choice.

6. Cost

Cost is often a deciding factor for many projects, and here PVC has a clear advantage over acrylic.

PVC is one of the most affordable plastics on the market. Its raw materials are abundant, and the manufacturing process is relatively simple, which keeps production costs low. For example, a 4x8-foot sheet of 1/4-inch rigid PVC costs roughly half as much as a similar acrylic sheet. This makes PVC ideal for large-scale projects like fencing, piping, or window frames where cost efficiency is a priority.

Acrylic is more expensive than PVC. The polymerization process for PMMA is more complex, and the raw materials are costlier. However, the higher cost is often justified by acrylic’s superior clarity, UV resistance, and impact resistance. For applications where these properties are critical—like high-end retail displays, art installations, or outdoor signage—acrylic is worth the investment.

7. Machinability and Workability

Both acrylic and PVC are easy to work with, but their machinability characteristics differ, which can affect how they’re cut, drilled, or shaped.

Acrylic is highly machinable. It can be cut with a variety of tools, including saws, routers, and laser cutters. It also drills easily and can be sanded to a smooth finish. When cutting acrylic, it’s important to use sharp tools and keep the material cool to prevent melting or cracking. Acrylic can also be glued using specialized acrylic adhesives, which create a strong, seamless bond—ideal for creating custom display cases or acrylic art pieces.

PVC is also machinable, but it has some quirks. It cuts easily with saws and routers, but it tends to melt if the cutting tool is too hot or moves too slowly. PVC also produces fine dust when cut, which can be harmful if inhaled—so it’s important to wear a dust mask and work in a well-ventilated area. When gluing PVC, solvent-based adhesives are typically used, which soften the plastic and create a strong bond—perfect for plumbing joints.

Acrylic vs. PVC: Ideal Applications

Now that we’ve covered the key differences between acrylic and PVC, let’s take a look at their ideal applications to help you choose the right material for your project.

Best Uses for Acrylic

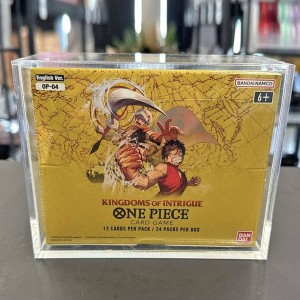

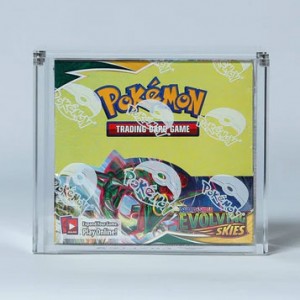

1. Display Cases

Acrylic display cases are ideal for showcasing collectibles, artifacts, or retail items. Their crystal-clear transparency rivals glass while being 10x more impact-resistant, preventing cracks from accidental knocks. Unlike glass, acrylic is lightweight, making it easy to mount on walls or place on shelves. It also offers UV resistance (with specialized grades), shielding delicate items like vintage toys or jewelry from fading. Customizable to various sizes—from small figurine cases to large museum displays—they often feature secure closures to dust-proof valuables. Their smooth surface is easy to clean with a soft cloth and mild cleaner, ensuring long-lasting clarity for prominent displays.

2. Storage Boxes

Acrylic storage boxes blend functionality with visibility, perfect for organizing cosmetics, office supplies, or pantry goods. Their transparent design lets you instantly locate contents without rummaging, eliminating the need for labels. Constructed from durable acrylic, they resist scratches and dents better than plastic or cardboard alternatives. Many come with stackable designs to save space, while hinged or sliding lids provide secure, dust-free storage. Food-safe acrylic options are great for dry goods like nuts or grains. They add a sleek, modern touch to any space—whether on a vanity, desk, or kitchen shelf—and are easy to wipe clean, maintaining their polished look over time.

3. Display Stands

Acrylic display stands are a staple in retail, museums, and homes for elevating items to eye level. Their minimal, transparent design ensures focus stays on the displayed object—be it a trophy, smartphone, or bakery pastry—without visual distraction. Available in diverse styles (pedestals, risers, tiered racks), they suit various items, from small jewelry to large art pieces. Acrylic’s strength supports significant weight despite its lightweight build, making it easy to rearrange displays. It’s also weather-resistant, suitable for indoor and covered outdoor use. Unlike metal stands, it won’t rust or scratch surfaces, and its smooth finish cleans effortlessly, keeping displays looking professional and tidy.

4. Service Trays

Acrylic service trays are a stylish, practical choice for hospitality and home use. Their transparent or tinted designs complement any decor—from modern restaurants to cozy living rooms—adding elegance to beverage or appetizer service. More durable than glass trays, they withstand accidental drops and bumps without shattering, ideal for busy environments. Lightweight construction makes carrying multiple drinks or dishes easy, reducing strain. Many feature non-slip bases to keep items secure and raised edges to prevent spills. Food-safe and easy to sanitize with soap and water, they’re perfect for catered events, coffee tables, or hotel room service, balancing aesthetics with everyday functionality.

5. Photo Frames

Acrylic photo frames offer a contemporary alternative to traditional glass frames, enhancing photos with their clear, glossy finish. They’re significantly lighter than glass, reducing wall-mounting stress and making them safer for kids’ rooms. Acrylic’s shatterproof nature eliminates the risk of sharp fragments, a key advantage for high-traffic areas. UV-resistant variants protect photos from sunlight fading, preserving cherished memories longer. Available in various sizes and styles—from sleek minimalist borders to floating designs—they add a modern flair to any space. Easy to assemble (many have snap-in backs), they’re simple to update with new photos, and their smooth surface wipes clean quickly to maintain clarity.

6. Flower Vases

Acrylic flower vases combine beauty with durability, ideal for home decor and events. Their clear design mimics glass, showcasing stem details and water clarity, while being shatterproof—perfect for households with kids or pets. Lighter than glass, they’re easy to move and arrange, whether on a dining table or mantel. Acrylic resists chipping and scratching, maintaining its sleek look with minimal care. It’s also waterproof and easy to clean—simply rinse to remove dirt or flower residue. Available in diverse shapes (cylinders, bowls, tall tapers) and tinted options, they complement any floral arrangement, from fresh bouquets to dried flowers, adding a modern touch to spaces.

7. Board Games

Acrylic board games with durability and clarity, ideal for both casual and competitive play. Acrylic game boards are scratch-resistant and warp-proof, outlasting traditional cardboard or wood boards even with frequent use. Game pieces (tokens, dice, counters) made from acrylic are sturdy, colorful (via tinting), and easy to distinguish. Transparent acrylic components like card holders or dice trays add functionality without cluttering the play area. Customizable acrylic inserts organize pieces, reducing setup time. Unlike plastic, acrylic has a premium feel, elevating the gaming experience. It’s easy to clean with a damp cloth, ensuring game components stay in top condition for years of family nights or tournament play.

Best Uses for PVC

Piping and Plumbing

Rigid PVC’s chemical resistance and compressive strength make it the top choice for water pipes, drain pipes, and irrigation systems. It’s affordable and resistant to corrosion.

Construction Materials

PVC is used for window frames, door frames, fencing, and siding. Rigid PVC is strong and durable, while flexible PVC is used for weatherstripping and gaskets.

Chemical Storage and Processing

PVC’s resistance to acids, alkalis, and solvents makes it ideal for chemical storage tanks, lab sinks, and industrial piping.

Flooring and Wall Coverings

Flexible PVC is used for vinyl flooring, wall panels, and shower curtains. It’s water-resistant and easy to clean.

Electrical Insulation

PVC is used to insulate electrical wires and cables due to its flexibility and resistance to moisture and chemicals.

Common Myths About Acrylic and PVC

There are several myths and misconceptions about acrylic and PVC that can lead to poor material choices. Let’s debunk some of the most common ones:

Myth 1: Acrylic and PVC Are Interchangeable

This is one of the most common myths. While they’re both plastics, their properties (like transparency, chemical resistance, and heat resistance) are vastly different. For example, using acrylic for a chemical storage tank would be dangerous, as it’s sensitive to solvents. Similarly, using PVC for a high-end retail display would result in a hazy, unattractive finish.

Myth 2: Acrylic Is Indestructible

While acrylic is more impact-resistant than glass, it’s not indestructible. It can crack under extreme pressure or if dropped from a height, and it’s prone to scratching. It also melts at high temperatures, so it should never be exposed to open flames or extreme heat.

Myth 3: PVC Is Toxic and Unsafe

PVC does release harmful chemicals when it burns or decomposes, but when used correctly (in applications like piping or flooring), it’s safe. Modern PVC products are also manufactured with additives that reduce toxicity, and they’re regulated by safety standards in most countries. However, it’s important to avoid inhaling PVC dust when cutting or machining the material.

Myth 4: Acrylic Yellowing Is Inevitable

While uncoated acrylic can yellow over time with prolonged UV exposure, most acrylic products on the market are treated with UV inhibitors that prevent yellowing. If you choose a UV-stabilized acrylic, it can maintain its clarity for decades, even outdoors.

How to Choose Between Acrylic and PVC?

To choose the right material for your project, ask yourself the following questions:

1. Do I need transparency?

If yes, acrylic is the best choice. If transparency isn’t a concern, PVC is more affordable.

2. Will the material be exposed to chemicals?

If yes, PVC is more resistant. Avoid acrylic for chemical-related applications.

3. Will the material be used outdoors?

Acrylic’s UV resistance makes it better for long-term outdoor use. PVC can be used outdoors but may require UV stabilizers.

4. Is impact resistance critical?

Acrylic is more impact-resistant than PVC, making it better for safety applications.

5. What’s my budget?

PVC is more affordable for large-scale projects. Acrylic is worth the cost for applications where clarity or UV resistance is key.

6. Will the material be exposed to high temperatures?

Acrylic has higher heat resistance than PVC, so it’s better for high-temperature applications.

Final Thoughts

Acrylic and PVC are both versatile, durable plastics, but they’re not interchangeable. Acrylic excels in clarity, UV resistance, and impact resistance—making it ideal for displays, skylights, and safety applications. PVC, on the other hand, is affordable, chemically resistant, and strong—perfect for piping, construction, and chemical storage. By understanding the key differences between these two materials and considering your project’s specific needs, you can choose the right one to ensure success, durability, and cost-efficiency.

About Jayi Acrylic Industry Limited

Jayi Acrylic is a professional custom acrylic products manufacturer based in China, with over 20 years of specialized experience in designing and producing custom acrylic products. We blend diverse design concepts with premium acrylic craftsmanship to create durable, elegant products tailored to global clients’ needs.

Our custom acrylic product range includes display cases, storage boxes, display stands, service trays, photo frames, flower vases, board game components, and more—all crafted from high-quality cast acrylic for unmatched impact resistance, clarity, and long-lasting shine. We offer full customization: from etched brand logos and personalized patterns to tailored sizes, colors, and combinations with metal/wood accents.

With a dedicated team of designers and skilled artisans, we adhere to strict quality control and respect clients’ diverse usage scenarios. Serving commercial retailers, corporate clients, and private customers worldwide, we deliver reliable OEM/ODM solutions, on-time delivery, and competitive pricing. Trust Jayi Acrylic for custom acrylic products that meet functional needs, elevate usage experience, and stand the test of time.

Have Questions? Get A Quote

Want to Know More About Custom Acrylic Products?

Click the Button Now.

You Might Also Like Other Custom Acrylic Products

Post time: Dec-09-2025